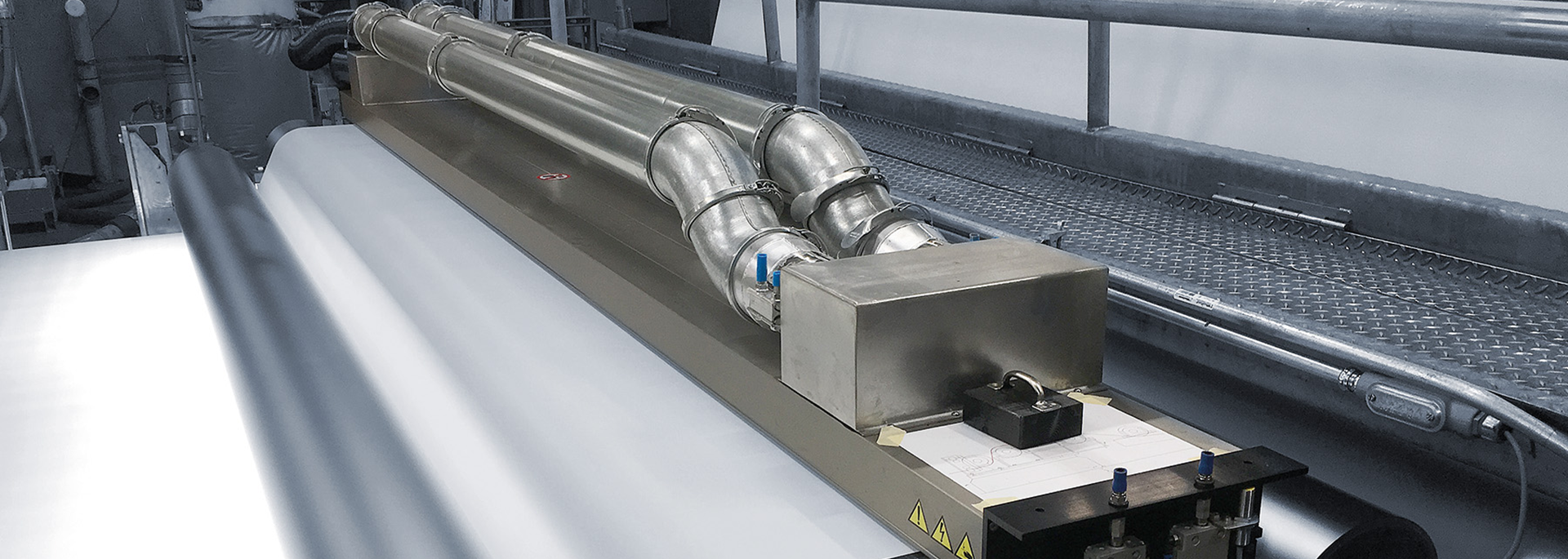

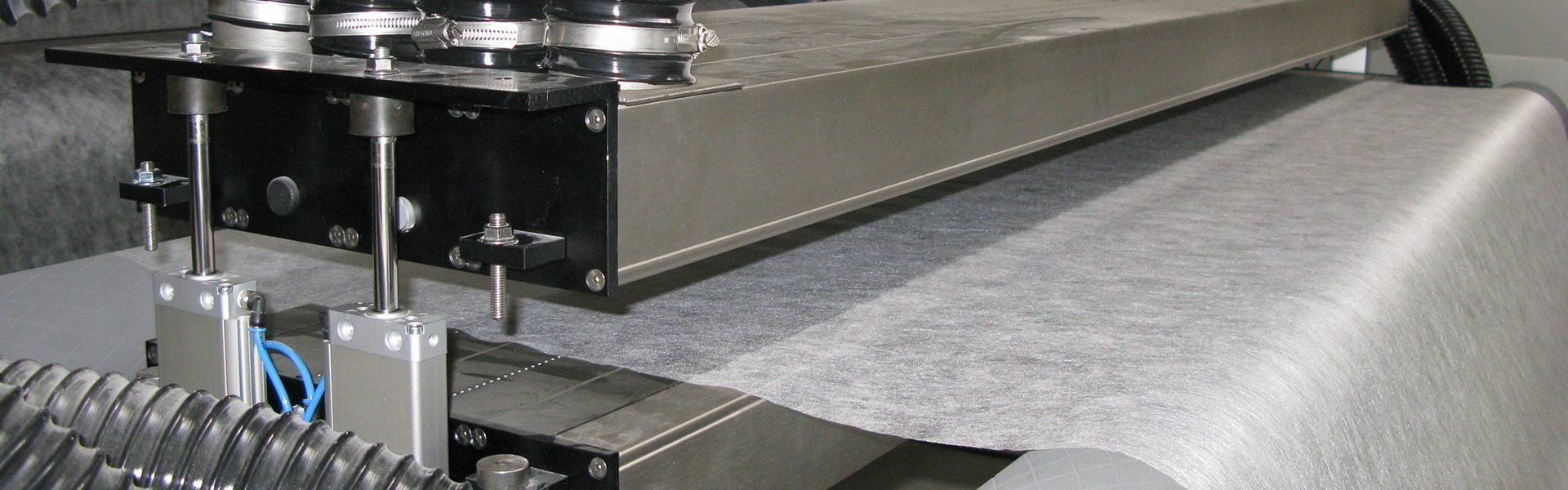

We are manufacturing web cleaning equipment and have more than 50 years experience with industrial dust removal in reel-to-reel and sheet-fed production processes. Our specific systems for corrugated board, tissue, non-woven, film, glass, glass fiber, printing and other finishing assure you of the best web cleaning solution for your application.

Over 7.000 installations worldwide show that KELVA is a proven partner for dust and contamination free production. We develop profitable and customizable web cleaning and dust removing systems for any material and dust load. All of our equipments can be easily integrated or retrofitted.

KELVA’s promise to you: Your production will be cleaner, safer, faster and more reliable through implementing dust eliminating systems from KELVA. Through web cleaning you won’t loose any production speed, but you will increase your production efficiency and lower your maintenance costs.