Research into the behavior of dust and dirt particles inside KELVA web cleaning systems is elementary for the development of new products. KELVA’s R+D department is breaking new ways with highspeed imaging.

With high-speed imaging, one of the core competencies of the CHROMOS Business Unit Industrial, processes that cannot be seen by the human eye can be made visible thanks to frame rates of several thousands of images per second.

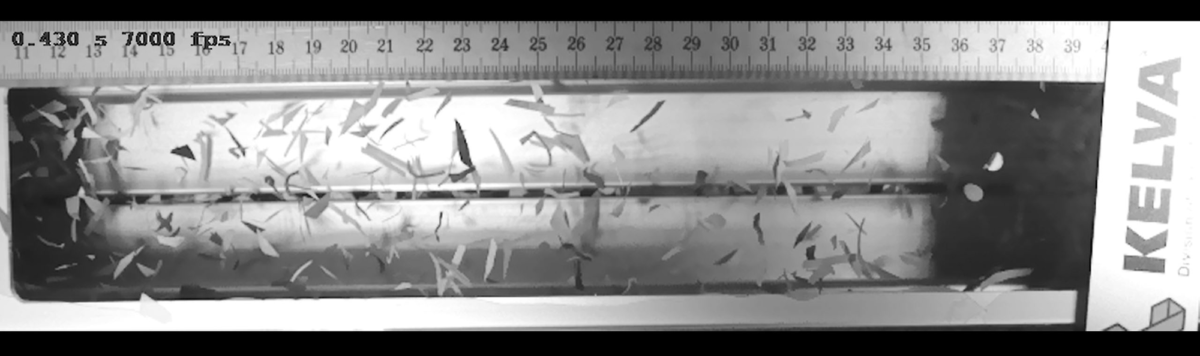

A cross-departmental team has now used this technology for a special test set-up to gather data on the on the behavior of dust and dirt particles and to gain deeper insights for research and development.

Swedish creativity, tested and made in Switzerland

All web cleaning solutions from KELVA are completely developed and produced in-house. Product development and engineering are located in Sweden, while production takes place in Switzerland.

Our production facility in Dielsdorf houses a test laboratory

where new web cleaning solutions for various materials and applications are regularly tested as well as demos are carried out. The interdisciplinary team of KELVA and CHROMOS Industrial developed the test environment for the purpose of visualizing the abrasion behavior in the new web cleaner TLX.

Normally simulation programs are used to gain knowledge about the real web cleaning process and effect. The idea behind this test project was to verify these results and, above all, to record on film how different types of dirt particles settle and move inside the web cleaner.

Special insights

Thanks clear test objectives and careful advance planning, the test and recording sequences could start quickly after setting up the camera. What had already been suspected and simulated was confirmed. But surprizing was to realize, how long the particles stayed in the web cleaner.

“The video helped us to understand the subtle differences in the behavior of the particles as a function of their properties, the air movement and the vacuum effect. This opens up the possibility for us to improve existing and future web cleaning solutions for different contaminants and material conditions”

Paul Nord, KELVA Sales Director“There are a number of factors that affect the behavior of the particles inside the cleaner. The place where they

Annika Wigren, KELVA Product Engineer

get inside, as well as their size and shape, determine the movement and, most importantly, how long the particles stay in the cleaner. The goal, of course, is to get them out as quickly as possible, to reduce the risk of blockage or clogging of the profile inlets and outlets”

Coordinated and evaluated accross divisions

This test run also pointed out the great opportunity that exists within the CHROMOS Group, to develop cross-divisional products and specific technical solutions for our customers.

Our experts will be happy to help you. Contact us!