Web Cleaning for Tissue

Maximizing Efficiency and Product Quality with KELVA’s Advanced Web Cleaning Solutions for Tissue manufacturing and converting

In tissue manufacturing and converting, maintaining a clean and dust-free environment is critical for ensuring the highest product quality. Dust and debris can impact the efficiency of the converting process, reduce the quality of tissue products, and pose risks to machinery and personnel.

KELVA’s advanced web cleaning solutions are designed to remove contaminants at every stage of tissue production, ensuring superior product quality, improved operational efficiency, and a safer work environment.

Contact usCleaning your tissue web is essential

Tissue products, ranging from toilet paper to facial tissues and napkins, must meet high standards of cleanliness and hygiene. These products require manufacturing processes that minimize contamination, including dust, lint, and other particles, which can affect both the product’s performance and customer satisfaction.

Tissue manufacturing generates a significant amount of dust and lint, particularly during the crêping process, where fine fibers are released and can settle on the web surface or machinery. KELVA’s web cleaning systems are essential for keeping tissue production lines dust-free, ensuring operational efficiency, and delivering consistently high-quality, hygienic products.

Why do tissue require web cleaning?

The tissue production process, including steps like crêping, reeling, and rewinding, generates large amounts of lint and dust. This contamination can become embedded in the tissue web or entrained in the surrounding airflow, leading to decreased product quality and possible air emissions in the manufacturing environment. Dust and lint accumulation on machinery can also cause breakdowns, increasing maintenance needs and downtime. Furthermore, for tissue products such as napkins, where printing quality is a concern, removing particles and lint ensures a clean and clear final product. KELVA’s web cleaning systems address these challenges, delivering cleaner tissue products and optimizing production efficiency.

Sources of Dust and Debris in Tissue Manufacturing and Converting

In tissue manufacturing, dust and lint are introduced at various stages.

During the Crêping process, the tissue web generates significant lint, which adheres to the web and the surrounding environment.

In Reeling and Rewinding, a boundary layer of air on the tissue web traps lint and particles, leading to contamination.

Additionally, external environmental dust can further compromise the cleanliness of the final product. Without efficient web cleaning, these contaminants can cause defects and operational issues in subsequent production stages.

Benefits of web cleaning in tissue production and processing

KELVA’s web cleaning systems offer a comprehensive solution to the key challenges in tissue production and processing. By enhancing product quality, improving operational efficiency, safeguarding worker health, and reducing waste, these systems ensure that manufacturers can maintain high standards while boosting productivity and profitability.

Enhanced Product Quality

KELVA’s web cleaning systems ensure tissue products are free of dust and lint, resulting in higher-quality, hygienic tissue rolls. This is particularly important for products like napkins, where cleanliness impacts both usability and printing clarity.

Improved Operational Efficiency

Dust buildup on converting machinery can lead to frequent stoppages and premature wear. KELVA’s web cleaning solutions help prevent these issues by removing contaminants, ensuring smooth operations, reducing downtime, and extending equipment life.

Worker Health and Safety

Tissue production generates airborne lint and dust, which can negatively affect the workplace environment. By removing these contaminants, KELVA’s web cleaning systems help maintain a cleaner, safer work environment, reducing respiratory risks for workers and improving overall air quality.

Reduced Waste

Contaminants on the tissue web lead to product defects, resulting in waste and increased production costs. KELVA’s web cleaning systems reduce these defects, improving production yield and enabling more efficient use of raw materials.

Cost Savings

By improving product quality, reducing waste, and minimizing equipment downtime, web cleaning systems ultimately lead to cost savings for tissue manufacturers and converters.

What is the best web cleaning solution for tissue?

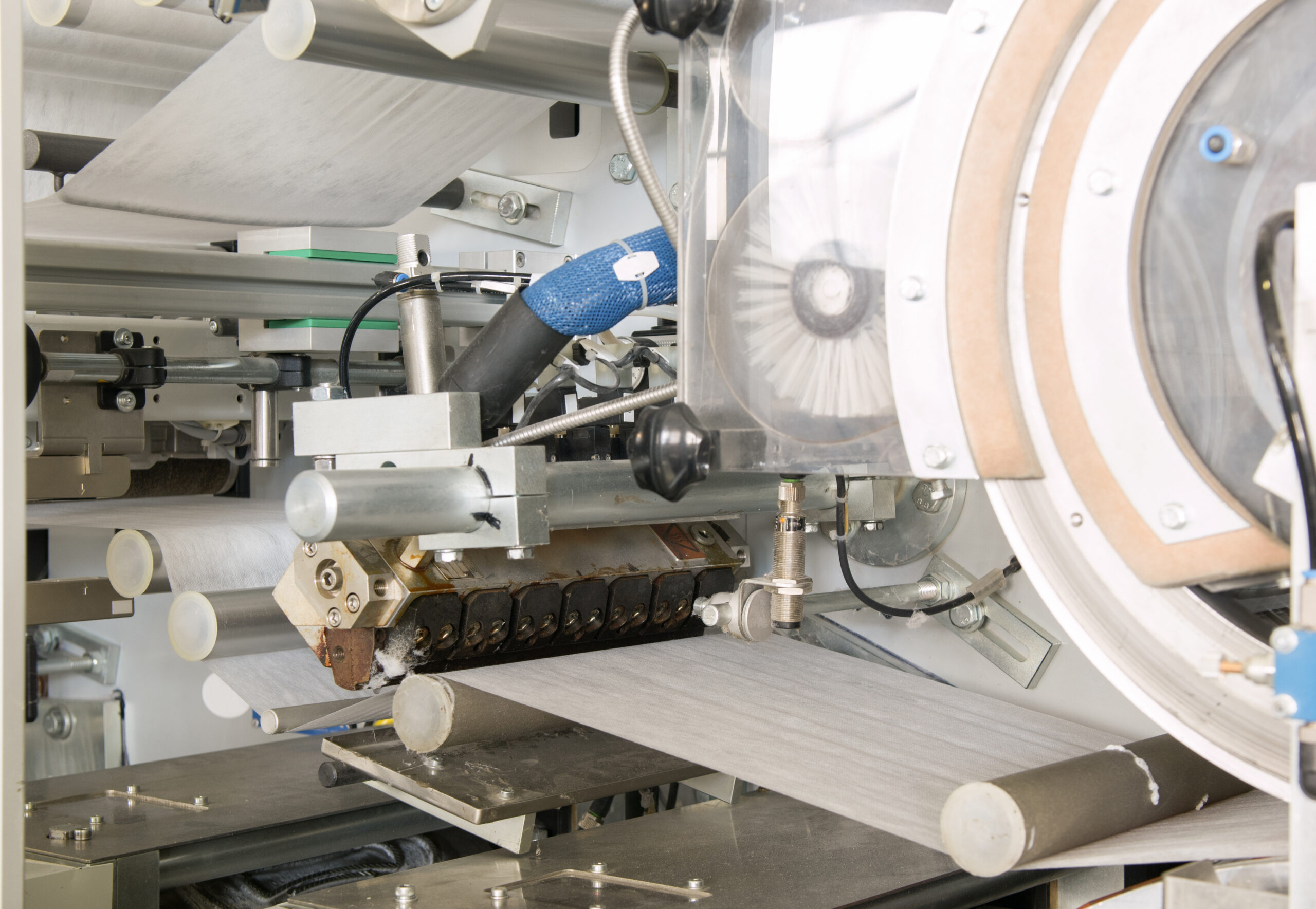

In tissue production and processing, non-contact systems such as our TL or HS line for example, use airflows to release contaminants into the air and then vacuum it into a capture and filtration system.

KELVA has developed special non-contact web cleaner heads suitable for cleaning glass fiber webs. These heads have a special slot configuration for the vacuum and blowing air to give extra support to the web when passing the cleaner.

Installation examples

contact

Our experts will be happy to help you. Get in touch with us!